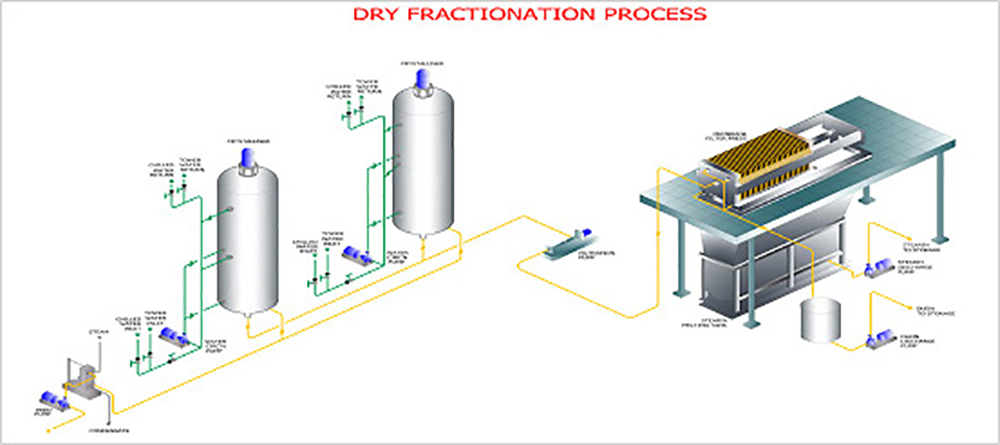

With Oiltek Dry Fractionation Plant you can transform your feedstock into more new oil products – each with its own unique properties and applications.

Fractionation is a physical modification processes, there are no chemical contact to the products. In the dry fractionation process, costly or hazardous chemical additives is not in use, no oil loss and no contamination of the oil because it produces no effluent, the dry fractionation process is also environment friendly.

- Design features that increase profitability by reducing utilities consumption and increasing yield and fraction purity.

- Hybrid cooling coils that provide higher yield yet shorter cooling time required.

- Tall, slim crystallizers and programmed agitator speed create an efficient but gentle slurry flow during cooling to enhance heat transfer to the coils yet preserve the quality of the stearin crystals.

- Lower dish end and radial lower paddle facilitate slurry circulation and prevent slurry settling to the bottom.

- Indirect cooling control continually controls the temperature of the cooling water to further ensure even slurry cooling and controlled crystal growth.

- Fully automated control of the complete crystallization and filtration process leads to consistent productivity. The cooling cycle for each crystallizer is control by programmable temperature controller.

- Use of cooling water initially for economic cooling and followed by chilled water.

- Multiple fractionation flexibility: Single Fractionation, Double Fractionation, Palm Mid Fraction and Stearin Fractionation